More flexible production and more at Kemper System

YAVEON makes it possible

Read how Kemper managed to join the existing ERP and, in parts, the outdated PPS system and how they created a solid base for working on one platform with consistent master data and continous workflows.

Everything at a glance

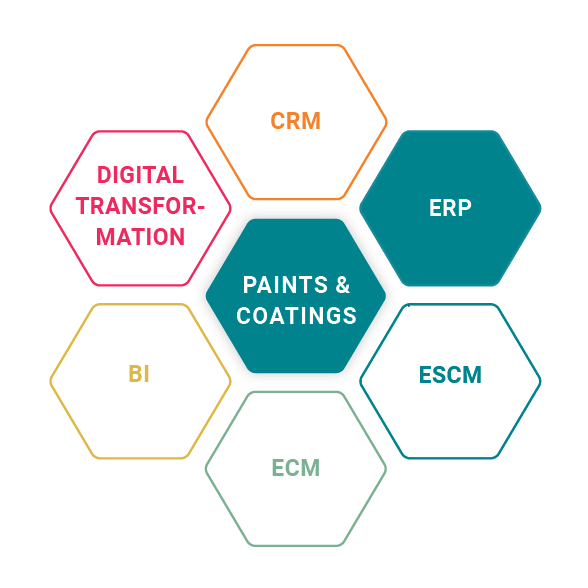

ProBatch, ProE-SCM, ProBI and DMS

Customer

KEMPER SYSTEM GmbH & Co. KG | www.kemper-system.com

Focus

Paints and Coatings

Company Size

Approx. 190 Employees

Operating Model

On-Premises

Countries

Germany, Great Britain, France,

Italy, India, China

Want to read the reference report in one document?

Sure - simply download the PDF version of the report

Which benefits does the YAVEON solution offer?

Visible results

CHALLENGE

Kemper wanted to join the existing ERP- and in parts the outdated PPS-System. In addition Kemper wanted to create a solid base for working on one platform with consistent master data and continous workflows.

SOLUTION

The industry solution YAVEON ProBatch based on Microsoft Dynamics NAV, the communication platform YAVEON ProE-SCM for workflows, EDI and intercompany, YAVEON ProBI based on QlikView as well as YAVEON document management system were used.

USE

Today Kemper profits through flexible production, better planning and full batch traceability. Kemper is able to deliver more articles in less time never losing the overview with an orderbased bulk production with flexbile container-filling. The capacity was increased and the storage area was reduced.

Safe building products

Secure IT department

SME´s (smaller midsized companies), which are globally active, have to solve a fundamental conflict of objectives in the selection of business software: Firstly, they need to provide solutions that meet the legal requirements on financial accounting of the respective countries, must be multilingual and also have to be - for sales and logistics locations - easily constructed. Secondly, it is necessary to display a flexible, order-related production with a complete control of the supply chain and to ensure worldwide consistent master data, intercompany processes and evaluations. Kemper System has accepted this challenge in its long-term corporate development and relies on the Microsoft platform.

Kemper System initially started in the year 1957 as coating and paint manufacturer and developed in 1969 the first liquid plastic for roof insulation. Since 2004, Kemper produces primarily solvent-free products and uses consistently sustainable raw materials. In this niche, Kemper is the market leader worldwide. The liquid plastics are used on flat roofs and balconies as an intermediate layer. Kemper also manufactures decorative coatings, which are widely used in the US on terraces of penthouses or viewing platforms of skyscrapers in New York. As a further string, the company delivers a three-layer protection against falling for glass and skylights. The coating acts like a second skin and prevents a fall if the dome collapses under the load.

Kemper System, which is part of the IBG Holding since 1985, pursues a long-term internationalization strategy. A plant in the US was founded in 1999. Kemper bought in 2007 a market companion in Germany. Offices in the UK, France, Italy, India and China already secure global market access. Whereby Kemper is going to open production sites in Asia in the upcoming years.

Global Master Data Management

„With the acquisition of the German plant in Coesfeld and the imminent merger of the two companies, it was necessary to consolidate the existing ERP- and partly outdated PPSsystems,“ says Dirk Schüßler, project manager for Microsoft Dynamics NAV at Kemper System. At the same time, Kemper wanted to create the basis to work on a sole platform with standardized master data and integrated workflows. Kemper started in 2009 the ERP-selection to enable for the two companies in Germany a clean transfer of operations. „We have specifically considered how we can build a longterm IT strategy. Because of the internationalization was clear, that the existing software from Diamond, Dibac and the others offer not enough support, „says Schüßler firmly. Three providers were shortlisted. „SAP does not fit in with our corporate size with 130 employees in Germany and 45 in the US. One really has to afford that, „says Schüßler.

When choosing Microsoft Dynamics, Schüßler finally was convinced because it is globally available to 100% and can map all local features. Not least because strong partners provide the necessary add-ons in all countries. „The modular design of Dynamics NAV enables us to map the specifics of each country‘s companies, but to maintain the central services such as contact management and master data uniformly.“ In addition, Kemper`s rest of the business IT is also on the Microsoft platform. While Microsoft Dynamics is fully sufficient in the sales offices for standard operations today, the business processes at the production sites are much more complex. Here, an industry solution that seamlessly integrates into Microsoft Dynamics is very welcome. Additionally, intercompany processes, EDI and accounting with central regulators are not displayed in the Dynamics NAV standard.

After thorough research and review, Kemper System chose in 2010 the Dynamics Partner YAVEON with its industry solutions for roduction and supply chain management. „We liked that the company fully focused on batch leaders in specialty chemicals and already had good references,“ Schüßler recalls. „It was also important to include the key user’s right from the beginning, what also YAVEON has recommended to us. This key user system still serves us today."

It was also important to include the key user’s right from the beginning, what also YAVEON has recommended to us. This key user system still serves us today.

Dirk Schüßler, KEMPER SYSTEM GmbH

Reorganization

Towards order-related production

Reorganization towards order-related production

The manufacturing processes were changed during the ERP implementation in Germany. „We wanted to produce more flexible, plan better and wanted to fully track the original batch“ says Schüßler. Therefore Kemper focuses since then on order-based bulk production with flexible drum filling. „This allows us to deliver more products in less time and still not lose track of the use of the individual batches. Similarly, the capacity could be increased and the storage areas could be reduced, „Schüßler renames the benefits.

It needs a lot of persuasion among employees when processes are new defined from one day to another - when scanners, labels and the like change the operation. „As a company, one has to rely on the advice from the provider and the process definitions of the industry solution. But it has been shown that the processes could be very well adapted to the specific needs of Kemper, „says Schüßler.

The existing hazardous goods system has been fully integrated into the value chain. The expert system receives the recipes from the ERP and classifies them. NAV prints the hazardous material labels according to GHS. The hazardous material certification sheets are simultaneously issued with the delivery note. Also the document management system could be integrated in a simple way. „This demonstrated the experience of YAVEON to integrate such third-party systems into functioning processes,“ says the project manager.

With this batch traceability, Kemper System receives at any time the necessary certifications of its products. „We completely handle in Germany and the USA in the ERP system the full recipe development, monitor the originating raw material batch and control the production and filling.“

Microsoft supports our long-term vision

Schüßler already sees the further strategy for the international management quite clear.

The data center for Europe is located in Germany, with production sites in Germany, Italy and the sales offices. Furthermore, there are already data centers in the US and India. Schüßler will expand these successively in accordance with the long-term corporate strategy. These data centers control independently the regions, but are linked to each other through VPN tunnels. QlikView consolidates all data and the management has an overview of the Group. Through the consistent use of the standard of Microsoft Dynamics in the less complex sales offices, Schüßler utilizes that they always have the current version, soon NAV 2016. Firstly, the versions vary by country, so in France the customary payment transactions can still be done by bills, on the other hand the add-on YAVEON ProE-SCM allows that internal orders are entered only once in the sales offices and automatically create the sales orders and delivery notes at the production sites. „With this we benefit from the digital processing of the supply chain and the stringent master data management. Data is always entered only once.“

We made the right choice to choose Microsoft Dynamics NAV for a number of reasons.

Dirk Schüßler, KEMPER SYSTEM GmbH

Reasons for

Microsoft Dynamics NAV

„Firstly, the standard is now very easy to use and integrates more and more into the rest of the Microsoft 365 world. Soon the benefits of cloud adoption will outweigh the concerns. On the other hand, the extensive partner landscape offers all necessary and NAV certified modules, which the standard cannot handle innately. NAV offers us the different local versions, which are used in different clients, but don’t interfere with the big picture. Lastly the management of the platform is consistent, which saves IT costs."

Six tips from Dirk Schüßler for all ERP project managers:

- You need a clear vision of where the company will be in 10 years. The ERP system has to match it.

- Bear in mind that an ERP implementation turns a company upside down and customizes workflows. Involve key users right from the beginning.

- Calculate that there will be points of friction with the staff and also with the provider

- Always keep the overall objectives in view. Partial optimizations must never be at the expense of the whole.

- Search from the beginning an experienced industry partner.

- Later on you will know more. So start small and develop the solution with the key users.