EDI connection despite tight time frame

At wimatec MATTES

Read the report to find out how wimatec MATTES implemented a direct warehouse connection of partners as well as automated order processing and managed to handle the company's growth.

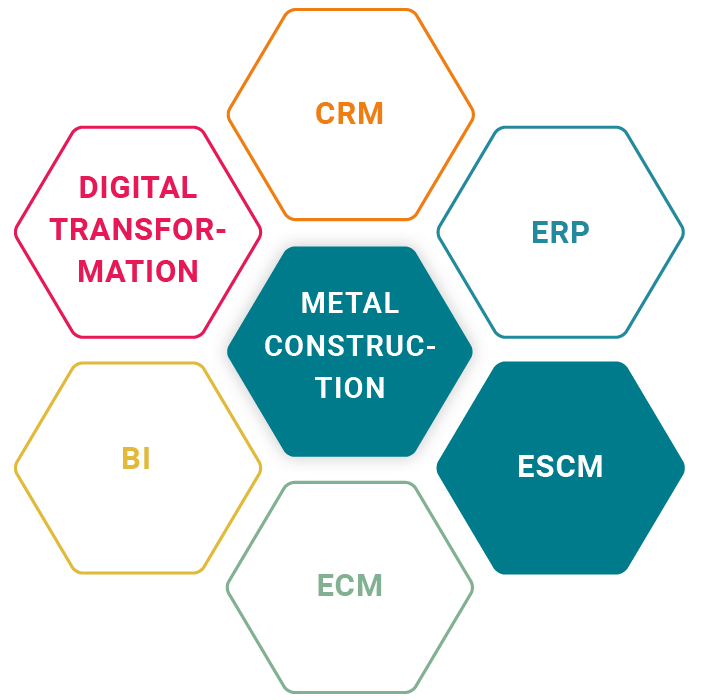

Everything at a glance

YAVEON ProE-SCM: Direct connection of partners

Client

wimatec MATTES | www.mattes-gmbh.de

Focus

metal construction

Employees

Approx. 70 employees

Operating Model

On-Premises

Country

Germany

Want to read the reference report in one document?

Sure - simply download the PDF version of the report

Which benefits does the YAVEON solution offer?

Visible results

CHALLENGES

- The rapid realization of an EDI connection in parallel with the ERP project

- Induction of users despite the tight time frame

SOLUTION

YAVEON ProE-SCM EDI Module

USE

- Direct warehouse connection to partners

- Automated order processing

- Supported sustainable growth of the company

Electronic Data Interchange

More efficient processes

The automated connection of companies via Electronic Data Interchange (EDI) brings obvious advantages: time-savings, more efficient processes, and digital order processing. On the other hand, there is the question of whether such a solution presents value for money.

wimatec MATTES, a manufacturer of harvester knives, faced this dilemma. The answer was simple.

Durable. Better!

More than a motto, the fundamental company philosophy is the statement, “Durable. Better!”. wimatec MATTES is an OEM manufacturer for the agricultural machinery industry. The company’s core technologies are hard coatings and heat treatment of wear parts. The result: ready-to-install components for agricultural engineering. “We wanted an EDI solution to connect partners to our ERP system,” recalled Michael Emhart, who is responsible for sales and development at wimatec MATTES.

On target with EDI

wimatec MATTES was introduced to YAVEON by a joint partner, who was implementing the ERP System Microsoft Dynamics 365 Business Central for the metal construction company. YAVEON ProE-SCM was able to cover all the requirements that wimatec MATTES set for the EDI solution.

What is YAVEON ProE-SCM?

YAVEON ProE-SCM is fully integrated into Microsoft Dynamics 365 Business Central, formerly NAV, and automates cross-system data exchange. The solution enables users to connect suppliers, partners, and customers seamlessly without the need for an external converter.

What does wimatec MATTES use?

- Import of delivery schedules (EDI and VDA standard)

- ESCM shipment orders

- Packing instructions

- Delivery notifications/export delivery notifications (EDI and VDA standard)

A project with a tight time frame

The ERP and EDI projects started in October 2019, and the planned go-live date was January 2020. It was November before the connection to the ERP system was possible - so things had to move quickly. “There wasn’t much time for extensive testing, and that worried me,” Mr. Emhart recalls. He spoke to his consultant about his concern, hoping to be reassured. “Right from the start, we took these concerns seriously and reacted immediately,” reports Wolfgang Riedle, software developer at YAVEON. The result: In on-site appointments as well as targeted training sessions, wimatec MATTES received the knowledge needed to efficiently manage the EDI solution.

Less effort - more time

Thanks to the YAVEON ProE-SCM EDI solution - fully integrated into the Microsoft Dynamics 365 Business Central ERP system - wimatec MATTES no longer has to record delivery call-offs manually. While sales orders used to be entered manually, the delivery schedule suggests which goods need to be delivered and when. The entire process now takes just a few clicks. Another advantage is the significant time savings. Since wimatec MATTES connected several companies simultaneously, this benefit is particularly noticeable, as order entry has become considerably easier. “The connection of our partners went absolutely smoothly, and our customers didn’t even notice the transition,” says Mr. Emhart happily.

"The connection of our partners went absolutely smoothly, and our customers didn’t even notice the transition."

Michael Emhart, wimatec MATTES

Go-live

Successful and remarkable

A successful and remarkable go-live

Despite the tight time frame, the project was implemented on time. The go-live took place as planned in January and was not the only highlight: at the same time, wimatec MATTES moved into new premises. A new ERP system, automatic connection via EDI, and a brand new office space - a excellent start to the new year in all respects.

Was it worth it?

To return to the question of whether the EDI connection was worthwhile, not only in terms of being beneficial but also from a financial point of view. “From a purely economic perspective, such a solution naturally costs money, and these costs must first be recouped. But the EDI connection enabled us to handle the growth of wimatec MATTES. The solution was necessary, and every cent was well invested,” sums up Michael Emhart.